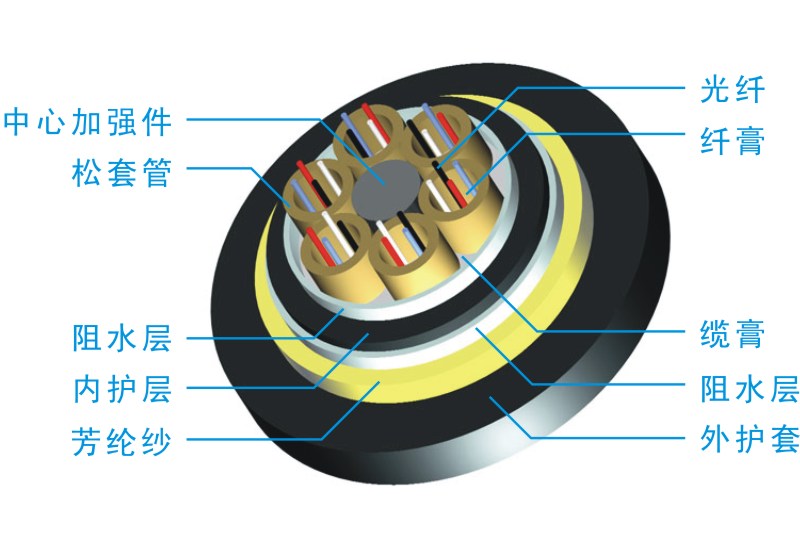

ADSS光缆采用松套层绞式结构,将250μm光纤套入高模量材料制成的松套管中,松套管内填充防水化合物。松套管(和填充绳)围绕非金属中心加强芯(FRP)绞合成紧凑的缆芯,缆芯的缝隙充以阻水油膏。缆芯外挤制聚乙烯(PE)内护套,然后绞合起加强作用的芳纶,最后挤制聚乙烯(PE)外护套或耐电痕(AT)外护套。

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

·产品特点 Characteristics

·可不断电架设

· Can be installed without shutting off the power

·采用AT护套,耐电痕性能优越

· Excellent AT performance, The maximum inductive at the operating point of AT sheath can reach

25kV

·重量轻、缆径小,减少了冰凌、风力影响和对塔架、支撑物的负荷

· Light weight and small diameter reducing the load caused by ice and wind and the load on towers

and backprops

·跨距大,最大跨距超过1000m

· Large span lengths and the largest span is over 1000m

·具有优异的抗拉性能和温度特性

· Good performance of tensile strength and temperature

·预期寿命可达30年

· The design life span is 30 years

·产品应用 Application

ADSS光缆的设计充分考虑了电力线路的实际情况,适用于不同等级高压输电线路。对于10kV和35kV的电力线路可采用聚乙烯(PE)护套;对于110kV和220kV的电力线路则必须通过计算电场场强分布来确定光缆挂点并采用耐电痕(AT)外护套。同时,精心设计芳纶的用量和完善的绞合工艺以满足不同跨距的应用要求。

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.