冷弯机是一台现代化机械设备产物之一,冷弯机采用数控系统作为主系统,液压体统、机械传动系统作为辅助系统,冷弯机在使用时具有传动平稳,压力大等特点,能准确定位,大幅度提高隧道工字钢加工精度。冷弯机在我国广泛应用于公路隧道、铁路隧道、地铁隧道、水利水电引水涵洞、天然气管道、通信管道、地下通道等各地施工工程。其优点有:尺寸精度高,扭曲变形小,弧度圆滑。我公司可根据用户的不同需要,搭配不同的部件,实现对钢轨、工字钢、H钢等材料进行冷弯加工,效率高、易运输、操作方便等

冷弯机主要参数

总功率【12Kw】

电压【380V】

液压系统压力【20Mpa】

油缸推进速度【1-13mm/s】

主驱动轮转速【7r/min】

最小弯曲半径【1.5m】

重量【2380kg】

外型尺寸【2500mm×1500mm×1200mm】

冷弯机,是以型钢为原料、通过连续冷轧成型。生产复杂断面型材,并可根据客户要求设计、制造不同规格的冷弯设备。行业施工中用数控冷弯机进行型钢加工,是钢拱架制造的必选设备。

冷弯机可用于工字钢、矿工钢、U型钢、C型钢、角钢、槽钢、道轨、方钢、钢管等型钢的拱形卷圆、变径、定角弯曲。数控冷弯机主要应用于隧道,地铁,水电站,地下洞室等工字钢,槽钢弯曲。数控冷弯机采用数显编码器编程,使液压操纵系统定位准确,所弯型钢一次自动成型,效率高、操作方便。

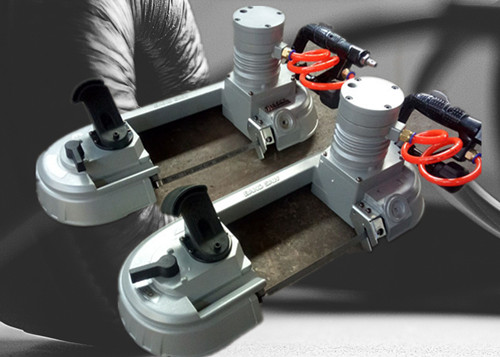

冷弯机构成(工作原理):

1、冷弯机是地道支护钢拱架加工制造的新式设备。数控冷弯机由底座、机械传动、冷弯体系、液压体系、电器控制体系和辅佐体系等六大有些构成。数控冷弯机工作时,将所需冷弯加工的型钢由辅佐体系的门式托架推放在两自动滚轮之间,发动数控冷弯机液压体系使液压缸推进燕尾槽和冷弯滚轮冷压型钢,待到达规划所需弧度时封闭液压体系,发动数控冷弯机机械传动体系,使自动滚轮滚动并依托摩擦力股动型钢平稳缓慢前行,然后完成接连冷弯工作。在冷弯结束时,封闭数控冷弯机机械传动体系 , 一起发动液压体系 , 使液压缸回收。将冷弯型钢放置在辅佐体系的门式托架上即可。这种冷弯工作,确保了原料的强度, 提高了支护钢拱架的质量,极大地提高了工效,操作简略、明晰。数控冷弯机与压床相比,具有杰出的工作性能。

2、为了习惯一些较差地质的施工工程区段,在地道的施工过程中,规划上常常运用钢拱架来支持维护,为了习惯运用钢拱架的运用数量增大,请求增高,然后规划了数控冷弯机这种设备。它确保了接连工作的可能性,而且节省了很多的人力和物力。

冷弯机的对比

1)比如对于一节长9m的工字钢拱架,工地原始办法是用氧气、乙炔每米割一个三角形缺口,用大锤敲打成弧形,但是这种做法破坏了工字钢的整体性,留下了多处烧伤。

2)在附近地区的工厂加工。但常常存在工厂太远,运输不便,加工费用高等问题,加大了成本。

3)使用冷弯机。这种要简单很多,只要将三相电引至加工区即可。虽然冷弯机投入近2万元,然而相对近300t工字钢的加工量来讲,这种投入完全是值得的。况且冷弯机加工时是连续的,工字钢之间全部电焊焊接,不存在下脚料,每加工9m可节约近50cm,成本大大降低。

冷弯机操作须知

1、将设备定放到一个基准面上进行校正,必须保持地面水平。

2、工字钢必须在水平的工作台上(带有滚动的工作台)工作。

3、使用前必须加油(减速机加30#机油,10公斤;油箱加46#液压油,50公斤,每月要更换新油)

4、电源连接是否符合标准

注意事项

1、电控箱、电液阀、行程开关等电器一定要保持清洁干燥,不得淋水。经常检查以上各部件的导线外套不得有破损,防止漏电。

2、搬运机器时,不要有大的颠簸,不得随意敲打机器的各部件。

冷弯机售后流程介绍:

1、数控冷弯机出厂保修期12个月(不包括易损件),免费提供损伤配件或整机更换。

2、免费数控冷弯机技术培训,达到熟练操作水平。

3、我们销售的主要是工程机械产品,结构大部分都比较简单,维护也非常的方便,不会因为一些小部件的损坏,导致整机无法正常运行。我们销售出去的产品如遇重大故障,或者客户无法解决的问题,我们承诺48小时之内派人到现场解决(一些偏远地区可能会延长时效)。

Bending machine is one of the modern mechanical equipment products, bending machine using digital control system as the main system, hydraulic system, mechanical drive system as an auxiliary system, bending machine in use has the characteristics of stable transmission, large pressure, accurate positioning, greatly improve the machining precision of tunnel i-beam. The cold bending machine is widely used in construction projects of highway tunnels, railway tunnels, subway tunnels, water conservancy and hydropower diversion culverts, natural gas pipelines, communication pipes and underground passageways in China. Its advantages are: high precision, small distortion and smooth arc. According to the different needs of users, our company can collocate with different components to achieve cold bending of rails, I-steel and H steel, with high efficiency, easy transportation and convenient operation.

Main parameters of cold bending machine

Total power [12Kw]

Voltage [380V]

Hydraulic system pressure [20Mpa]

Cylinder propulsion speed [1-13mm/s]

Main drive wheel speed [7r/min]

Minimum bending radius [1.5m]

Weight [2380kg]

Outer size [2500mm * 1500mm x 1200mm]

The cold bending machine is made of type steel as raw material by continuous cold rolling. The production of complex section profiles, and can be designed and manufactured according to customer requirements of different specifications of cold bending equipment. For the steel processing industry in the construction of CNC bending machine, is the necessary equipment for manufacturing steel arch.

Cold bending machine can be used for steel, I-steel, miners U steel, C steel, angle steel, channel steel, rail, Fang Gang, steel and other steel arch roll round, diameter, bending angle. The numerical control cold bending machine is mainly used in the tunnel, the subway, the hydropower station, the underground cavern and so on, and the channel steel is bent. Numerical control cold bending machine adopts digital encoder programming to make the hydraulic control system accurate, and the curved steel is automatically formed in one time, and the efficiency is high and the operation is convenient.

Composition of the cold bending machine (working principle):

1, bending machine is a new equipment for tunnel support steel arch manufacturing. The NC cold bending machine consists of six parts, which are the base, the mechanical transmission, the cold bending system, the hydraulic system, the electrical control system and the auxiliary system. The work of CNC bending machine, steel bending required by door bracket system to help push it between two roller, hydraulic bending machine CNC system to launch the hydraulic cylinder to promote dovetail groove and cold bending roller cold steel, to reach a required radian when planning closed hydraulic system, a numerical control forming the mechanical transmission system, the automatic rolling friction and relying on the femoral artery smooth steel moving slowly, and then complete the series of cold work. At the end of the cold bending, the mechanical transmission system of the NC cold bending machine is closed, and the hydraulic system is launched to make the hydraulic cylinder be recovered. The cold-formed steel is placed on the door type bracket of the auxiliary system. The cold work, ensure the material strength, improve the quality of the support steel arch, greatly improves the work efficiency, simple operation, clear. Compared with NC bending machine and press, with outstanding performance.

2, to the construction engineering geological section of some bad habits, in the construction process of tunnel in planning often use steel arch to support maintenance, in order to use number of used steel arch increases, request increased, then planning CNC bending machine of this equipment. It ensures the possibility of continuous work and saves a lot of manpower and material resources.