一般来讲,冷弯就是用冷弯机弯的,不加热;而热弯需要加热,所以其中就只有一个区别:冷弯有应力热弯没有。那么什么叫做应力呢?当材料在外力效果下不能进行位移时,它的几许形状和尺度将发生改变,这种形变就称为应变。材料进行形变时内部产生了大小相等但方向相反的反效果力反抗外力;把散布内力在一点的集度称为应力,应力与微面积的乘积即微内力或物体因为外因(受力、湿度改变等)而变形时,在物体内各部分之间发作相互效果的 内力,以反抗这种外因的效果,并力求使物体从变形后的方位回复到变形前的方位。

此类机器能弯曲的材质除去工字钢外还适用于矿工钢、U型钢、C型钢、角钢、槽钢、道轨、方钢、钢管等型钢的拱形卷圆、变径、定角弯曲。

最终,消费者一定要谨记的是,在工字钢冷弯机的选购中,不只需留意设备质量的好坏,最主要的是要挑选有售后保证的厂家收购,以保证冷弯设备这种大型设备在买回去今后有较好的质量保证,而且这样做对于冷弯设备的正常投入出产及后期的保护、修理也十分有利。

注意事项:

同样,矿山,水利、引水涵洞等工程是一样的,对于冷弯机的需求是一定的,那么为什么冷弯机行业一直处于尴尬的状态,就厂家而言冷弯机销量和产品的重要性一直属于附属产品,主要是因为,冷弯机在工地上使用时必然的,但是就冷弯机的使用情况来看,一台冷弯机使用寿命相对较长,同时,价格上来讲,厂家的利润不大,如果仅仅依靠冷弯机这一款产品来发展是不太现实的。

Generally speaking, cold bending is done by cold bending machine without heating, while hot bending needs heating, so there is only one difference: cold bending, stress and hot bending. So what's called stress? When the material can not be displaced under the external force, the shape and scale of the material will change, which is called strain. Material deformation which are of equal magnitude but opposite effect against external force; spread force at a point set of product is called stress, stress and micro area of micro force or object (because the external force, the change of humidity etc.) and deformation, internal force attack each other in effect among the various parts of an object, to resist the external effect, and strive to make the object from the deformed range back to the pre deformation range.

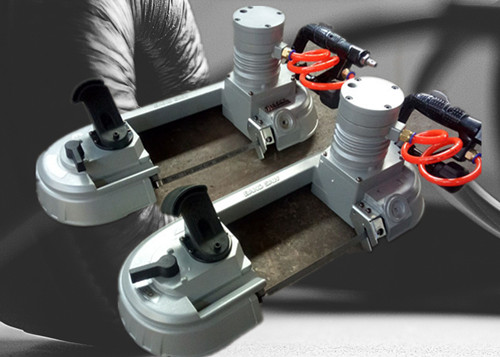

This machine can bend the material removed I-beam also apply to miners steel, U steel, C steel, angle steel, channel steel, rail, Fang Gang, steel and other steel arch roll round, diameter, bending angle.

The main parameters of WGJ-250 cold bending arch machine:

Outer size: (long x wide * high) 2.5m x 1.5m x 1.3m

Total power: 12Kw voltage: 380V

Pressure of hydraulic system: 20Mpa

Oil cylinder propulsion speed: 1-13mm/s

Main drive wheel speed: 7r/min

Minimum bending radius 2m

在选购冷弯设备时,要看设备的各零部件是不是设备到位,是不是出现松动,是不是部件有锈蚀表象,假如出现零部件松动、有锈蚀表象,哪怕是纤细的也最佳不要收购,因为这样的冷弯设备也许是他人用过的旧货,也许是存放较长时间没有用的设备,所以在收购冷弯设备时一定要细心调查、问询。

Secondly, when choosing the cold bending equipment, the equipment can be launched to investigate and listen to whether the work is normal. If Huang Lang heard that chaos ring bending equipment inside individual components is not sensitive, or loose fall bad appearance, this should particularly pay attention to this, don't buy cold equipment.

Finally, consumers must keep in mind that, in the purchase of I-beam machine, not only need to pay attention to the quality of the equipment, the most important is to ensure the selection of customer service to ensure the acquisition of manufacturers, the cold equipment of large equipment in the future to buy back a better quality assurance, and to do so for protecting the normal input of cold the production equipment and the late repair are very favorable.

Matters needing attention:

The cold bending machine belongs to the hydraulic machinery. Some people ask, why is there electric power? The electric cold bending machine also transforms the electric energy into the potential energy of the hydraulic oil, and finally comes to the cold bending machine to do the work and achieve the proper performance. So how do the cold-bending machines apply to those projects?

We will definitely see bender in the tunnel construction, tunnel construction will need to bend and I-beam, tunnel reinforcement, a series of processes, shotcrete and so on, to the inner wall of the tunnel reinforcement, so the tunnel construction is cannot do without bending machine, but appears to be important in bending machine, tunnel construction it is a two Taiwan is completely sufficient. When we use the I-steel cold bending machine, we need to choose the cold bending machine for the quantity and progress of the engineering.

Similarly, mining, water conservancy, water diversion culvert project is the same, is certain for bending machine needs, so why bending machine industry has been in the awkward state, on the importance of bending machine manufacturers sales and products has always belonged to the ancillary products, is mainly because the bending machine used on our site is inevitable, but use of a cold bending machine, bending machine with a relatively long service life, at the same time, in terms of price, the profits of manufacturers is not big, if only rely on the product to the development of bending machine is not too realistic.

The use of cold bending machine in engineering has influenced the sales of other products, such as tunnel construction, need cold bending machine will require Tunnel Shotcreting car, also need some other engineering machinery, like rig, excavator, loader, engineering machinery and equipment, so many manufacturers rely on small products such as bending machine to open other high profit products to market development. Cold bending machine has an important significance in such a role, as well, it is also playing an important role in various projects. .

The I-steel cold bending machine has played a good role in promoting and promoting the automation of the profile processing. The I-steel cold bending machine is developed on the original bracing bed. Generally, there are three bracing heads, arranged on the same plane, and maintaining a certain interval between each other. The commonly used bracing beds for I-steel cold bending machine can be divided into two types:

(1) the center is a moving head, and the two sides are static bracing heads. This kind of bed support dynamic support head is driven by a crank or eccentric, capable of reciprocating motion, so as to exert a force on the contradict profile; static hold head was support profile processing, but in order to meet the needs of the processing section of different size, the static hold head made before and after adjustment.

(2) the center is a static bracing head, and the two sides are moving brace heads. The supporting head of this kind of supporting bed is mostly driven by the oil cylinder, so the supporting head is actually an extension part of the cylinder piston rod, and its stroke can be regulated by the oil flow into the cylinder. The motion of the two brace heads needs to be kept in synchronization so that the bending deformation of the profile and the static bracing head are symmetrical.

During the operation of the I-steel cold bending machine, the operation rules should be strictly observed, and the operation should be stopped immediately and the reasons for stopping the machine should be stopped. At the same time, after the working of the I-steel cold bending machine, the oil pump should be closed immediately and the power supply should be cut off.

Xinxiang city in Electrical Equipment Co., Ltd. is a collection of workers