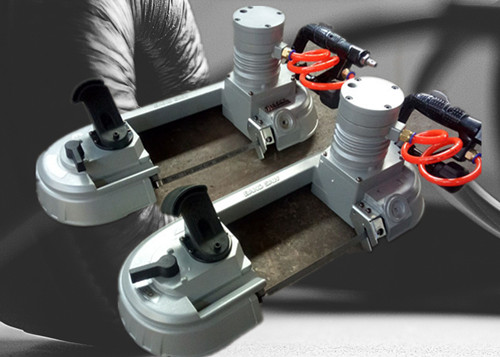

气动带锯主要用于刮板运输机链条切割、支护材料切割、金属锚杆切割、工作面抢险救援等。通过采用不同锯条规格,可以切割硬度不同的各种钢材材料。

气动带锯特点

1.气动钢材锯无需担心火花带来的危险,所以适用于煤矿及化工等危险环境作业,广泛用于切割大直径管道、槽钢、钢丝线缆等金属,非金属切割。

2.无火花切割锯,可在高温下、潮湿环境中作业无漏电危险。

3.气动防爆锯,结构紧凑,牢固可靠、重量轻便 携带方便,一人即可操作,降低工人的劳动强度,提高工作效率。

气动带锯性能

1、气动线锯采用井下压缩空气作为工作介质,适用于掘进或采煤工作面各种工作环境;

2、手持式气动线锯结构强度高,耐冲击,适应井下恶劣工作环境;

3、无火花气动线锯专利风冷结构和转速设计避免了切割过程火花的产生;

4、防爆气动线锯在井下爆炸危险环境中使用时可使用外注水或者乳化液对锯条进行冷却,提高使用寿命,同时消除火花隐患;

5、往复气动线锯采用循环式锯条进行切割,切割速度快,切割尺寸范围大;

6、安全气动线锯切割直径较大材料或连续作业时间较长可以采用专用支架支撑,大大降低劳动强度,提高工作的安全性。

7、小型气动线锯体积小,重量轻,便于井下移动。

气动带锯技术参数

工作压力:6-8KG

切割范围:U型钢、槽钢、工字钢、轨道钢、角钢、锚杆、钢板、钢管

有效切割直径:120mm

功率:1.5KW

锯片速度:132M/MIN

耗气量:0.6m/3min

重量:6KG

问:煤矿井下切割工字钢、U型钢、槽钢、角钢、锚杆、锚索、钢管等钢材,用什么工具?

答:推荐使用“FDJ型矿用手持式风动/气动切割锯”

问:煤矿瓦斯含量高可以使用吗?安全吗?

答:可以使用,风动切割锯以压缩空气为动力,采用进口材质的锯条,切割过程不会发烫,不会产生火花,无论是动力源还是切割接触部分都做到了冷切割技术。

问:操作方便吗?

答:手持式,质量轻,便携,更可以多角度切割,对于煤矿井下动力源非常好解决的

问:除去煤矿井下使用,还适用于其他场所吗?

答:除煤矿井下,在石油、天然气管道拆除和维修作业中也可以使用,另外对于防爆要求比较高的场所或化工车间都可以使用。

The pneumatic band saw is mainly used in the chain cutting of the scraper conveyor, the cutting of supporting materials, the cutting of metal bolt, and the rescue and rescue of the working face. Various steel materials with different hardness can be cut through the use of different saw bar specifications.

Characteristics of pneumatic band saw

1., pneumatic steel saws need not worry about the danger brought by sparks, so they are suitable for dangerous environment operations such as coal mines and chemical industries. They are widely used for cutting large diameter pipes, channel steel, wire and cable metals, and non-metal cutting.

2. no spark cutting saw can work without leakage at high temperature and humid environment.

3. pneumatic explosion-proof saw, compact structure, firm and reliable, light weight and easy to carry, one person can operate, reduce labor intensity, improve work efficiency.

Performance of pneumatic band saw

1, pneumatic wire by the compressed air as working medium, suitable for driving or working faces of various working environment;

2, a hand-held pneumatic wire structure of high strength, impact resistance, adapt to the harsh working environment of underground;

3, no spark wire pneumatic air cooling structure and speed of design patent avoids cutting spark;

4, explosion-proof pneumatic wire used in underground explosion hazardous environment can be carried out on the use of external water cooling blade or emulsion, improve the service life, and eliminate the hidden trouble of spark;

5, reciprocating pneumatic wire by using cyclic saw blade cutting, cutting speed, cutting size range;

6, pneumatic wire cutting large diameter material or continuous long work time can be supported by special support, greatly reduce the labor intensity, improve work safety.

7, small pneumatic wire has the advantages of small size, light weight, easy to move underground.

Technical parameters of pneumatic band saw

Work pressure: 6-8KG

Cutting range: U steel, channel steel, I-steel, rail steel, angle steel, anchor, steel plate, steel pipe

Effective cutting diameter: 120mm

Power: 1.5KW

Saw blade speed: 132M/MIN

Air consumption: 0.6m/3min

Weight: 6KG

Question: the cutting of I-steel, U type steel, channel steel, angle steel, anchor, anchor cable, steel pipe and other steel. What tools are used?

Answer: recommend the use of "FDJ type hand held pneumatic / pneumatic cutting saw"

Q: can the high gas content in the coal mine be used? Is it safe?

Answer: it can be used. Pneumatic cutting saw uses compressed air as the driving force and adopts imported material saw blade. The process of cutting will not burn, no sparks will be generated, no matter the power source or the cutting contact part, the cold cutting technology will be done.

Question: is it convenient to operate?

Answer: hand-held, light quality, portable, more angle cutting, the coal mine power source is very good to solve

Question: is it applicable to other places, except for the use of coal mine?

Answer: in addition to underground coal, it can also be used in oil and gas pipeline demolition and repair operations, and it can also be used for sites with high explosion-proof requirements or chemical workshop.